Using FuncX to execute Artificial Neural Networks on Remote Industrial Edge Resources: An application for fish processing industries

12 Mar 2021 - Ioan Petri, Ioan Chirila, Ciprian Chirila, Yacine Rezgui, Omer Rana, School of Engineering, Cardiff University, UK

Within the climate change agenda, research studies report that 15% of global energy is consumed by operations related to refrigeration and air conditioning in the fish industry, which highlights the need for smart energy management solutions. While fish processing industries have high energy costs with continuous refrigeration, air conditioning, and ice making processes, there is a real need to analyse and model energy use. One solution that can be applied to optimize energy use in energy consuming industries is the implementation of edge-based forecasting models. Such prediction models can detect and predict failures and also provide real-time energy optimization in various use case scenarios. For neural network learning, the local goal can be related to the error rate based on the quality and consistency of the historical data. From a global perspective, the edge orchestrator needs to achieve a tradeoff between local goals within an edge ensemble, while providing an improvement in the global goals at the scale of the entire edge infrastructure

We adopt such modelling principles to increase energy efficiency for a realistic industrial fish port in Milford Haven, South Wales. The smart industrial factory scenario involves energy simulation; local goals can identify the period over which a simulation is to be carried out in relation to a number of simulation instances that can impact the quality of results. We use an artificial neural network, for instance, to support simulation process at the level of industrial appliances and to have real-time reasoning capability in terms of control and actuation. We have used a funcX framework to allow users to register AI functions in a cloud-hosted service and remotely execute them on an accessible funcX endpoint.

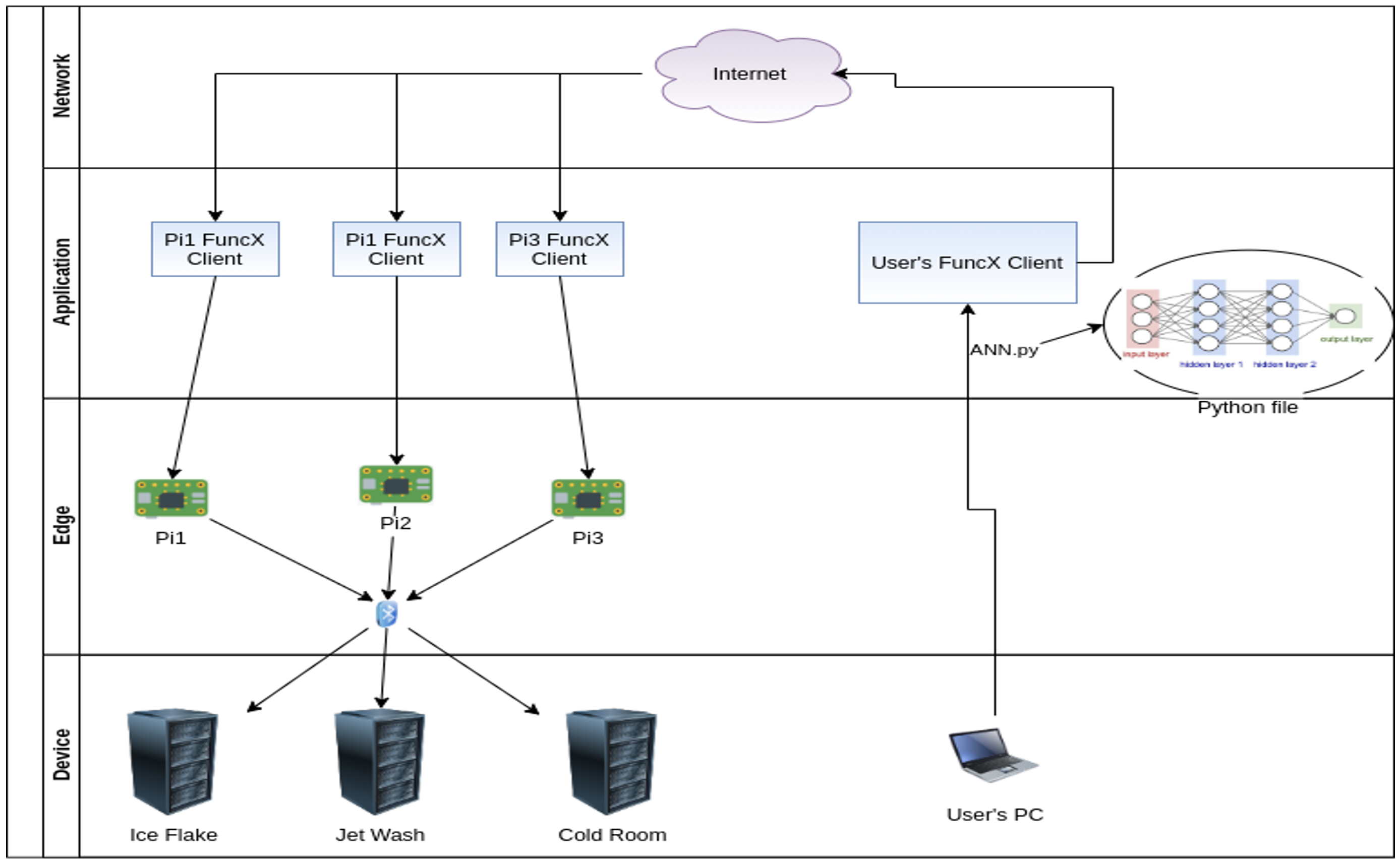

In our application, we use funcX as a mean to execute an ANN (Artificial Neural Network) that performs energy forecasting on a remote edge RaspberryPI device. As the RaspberryPI directly controls an industrial appliance, actuation setpoints are implemented periodically within the pilot appliances. The diagram below presents architectural layers supporting the execution of the edge funcX workflows with a view to deliver actionable energy decisions for the appliances.